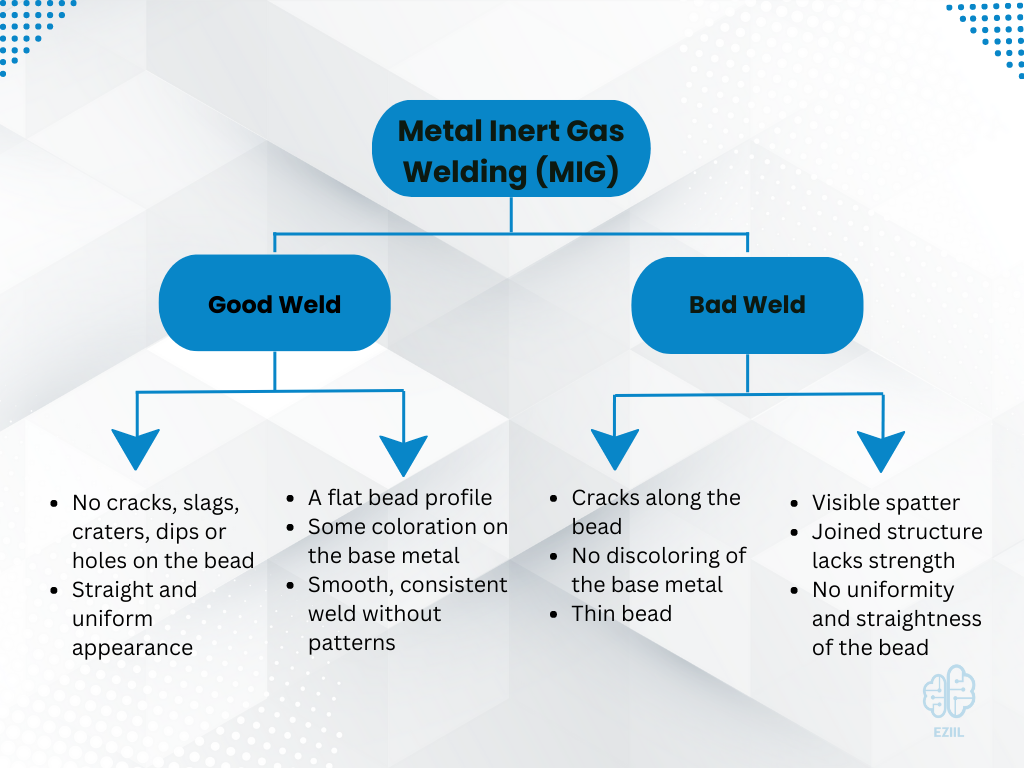

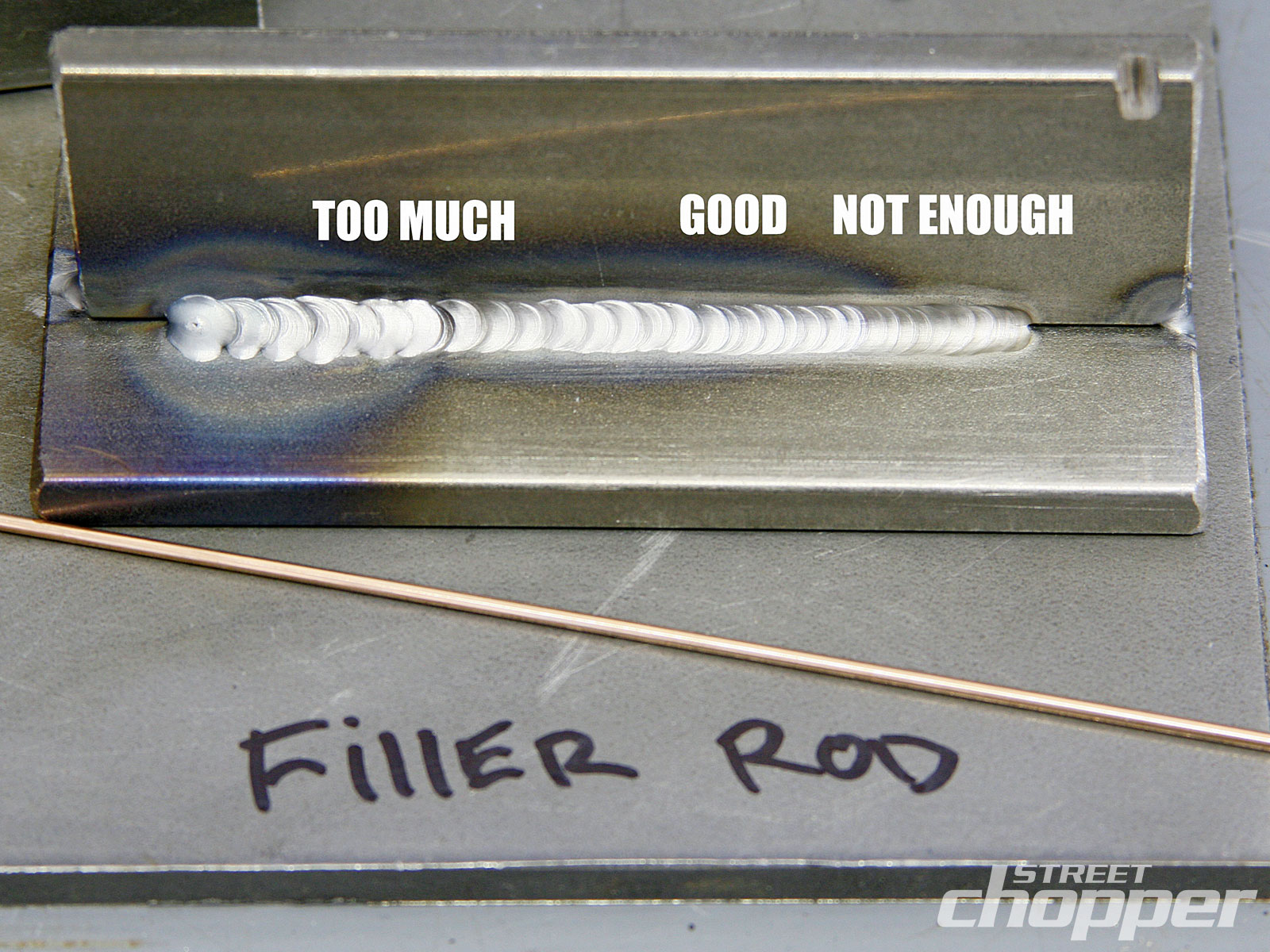

Impact on Product Performance and Safety. A good weld ensures a product will operate as intended under a wide range of conditions. It directly influences a device's functionality and longevity. Weld quality affects product performance in terms of how well it stands up to the tasks it will perform or endure. Good-quality welding also extends a.. Inaccurate torch adjustment, incorrect flame, travel speed, and improper weld surface cleaning can all have an impact on the weld bead produced by oxyacetylene. A good bead, on the other hand, is one that is consistent and free of flaws like holes or cracks. Good Weld. Smooth bead. No cracks or holes.

Good Weld vs Bad Weld 4 Methods for Proper Results and Testing Advice

Good Weld vs Bad Weld 4 Methods for Proper Results and Testing Advice

Good vs Bad Welds InDepth Examples and Images

Welding problems MIG Welding Forum

A Good Weld vs A Bad Weld Black Bull Engineering

Shan's GTAW (TIG) Blog. Good Weld Bad Weld Metallurgy

Does Your Equipment Have Bad Welds? YouTube

How to Spot a Bad Weld Vs Good Weld? (Updated July 2022)

Good and Bad Welds FCAW Wall Poster Hobart Institute of Welding Technology

How to Identify a Good Weld vs Bad Weld (with Pictures) WaterWelders

Good Weld vs Bad Weld 4 Methods for Proper Results and Testing Advice

Good Weld vs. Bad Weld Everything You Need to Know ( Spring 2023)

Good Weld vs Bad Weld 4 Methods for Proper Results and Testing Advice

How can you Identify Good Weld vs Bad Weld

Bad Weld vs Good Weld, 1F Plate Stick Welding, SMAW Welding welder junior YouTube

Good Vs Bad Welds

Shan's GTAW (TIG) Blog. Good Weld Bad Weld Metallurgy

Good Weld Vs Bad Weld Importance of Good Weld!

Good Weld Bead vs Bad Weld Bead Welding 101 YouTube

Learn The Secrets Of Good Weld VS Bad Weld Techniques!

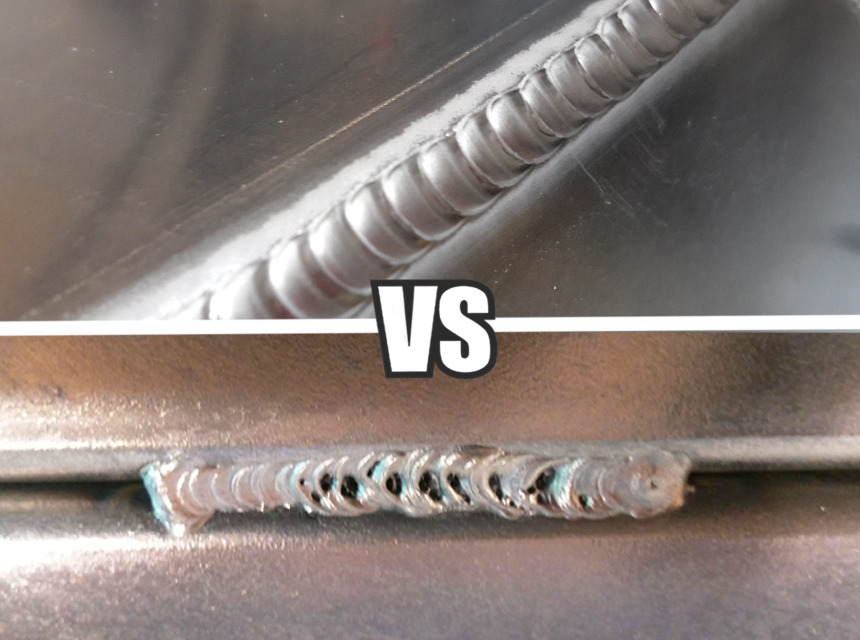

This is the number one culprit of a bad weld. And generally occurs in all types of welding i.e. Mig Welding, TIG Welding, Stick Welding, Oxy Welding, etc. 4. Undercutting. Undercutting in welding is the condition when the base metal or material is melted away where the next weld bead is to be deposited and thus results in a sharp nook.. Good Weld vs Bad Weld. Welding is a crucial part of many industrial processes, and the quality of welds can have a significant impact on the safety, reliability and longevity of fabricated products. Knowing how to spot a good weld from a bad one is essential for anyone involved in welding or working with welded materials.